By Maya Majueran

Industrial Zones

Industrial Zones are geographically designated areas that are earmarked by the government for the production of industrial goods and services. These zones normally enjoy a unique legal and economic status to promote investment from firms that might not otherwise be attracted. The prime objective was to enhance foreign investment and provide an internationally competitive and hassle-free environment for exports to be competitive globally. Zones play a key role in the rapid economic development of a country and global trade. If industrial zones are implemented successfully, they can help to generate employment, foreign direct investment (FDI), foreign exchange earnings, exports, and government revenues. In addition, industrial zones can facilitate skills upgrading, technology transfer, adoption of modern management practices, and economic diversification.

Belt and Road Initiative (BRI)

One of the major goals under the Belt and Road Initiative (BRI) is to provide unimpeded trade, thus Chinese businesses had helped build industrial zones in many countries along BRI routes. From Cambodia to Ethiopia to Belarus, industrial zones have become an increasingly important dimension of international cooperation within the framework of the BRI. BRI cooperation could make better use of such special zones and create more win-win results for participating countries.

To date, up to 140 partner countries have signed documents on Belt and Road cooperation with China. Sri Lanka is one of the critical members of BRI since its inception. There has been a large rise in Chinese investments in various projects in Sri Lanka since Sri Lanka became an active partner of BRI. The Hambantota Port project is one of those that, which initially started back in 2009, is now considered to be part of BRI.

Hambantota International Port (HIP)

The Hambantota International Port (HIP) is a deep-water port being developed in phases in Hambantota, southern Sri Lanka. This port is located 10 nautical miles to the major international east-west shipping route - the Suez Canal and the Strait of Malacca and well-positioned at a strategic location on the maritime gateway to India. For many centuries, Sri Lanka had been at the centre of the historical Silk Road connecting Europe and China. Generally, per day about 300 ships pass this route and create good business opportunities in the production of goods and services supported by efficient logistical facilities and less transaction cost.

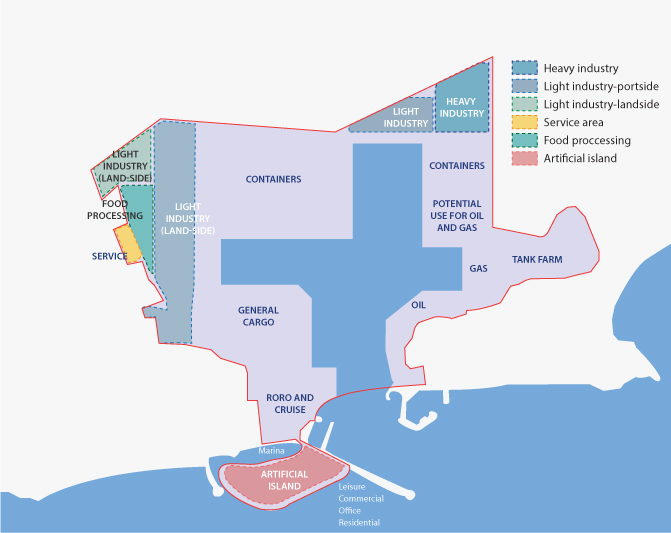

The HIP Industrial Park holds a little over two square kilometers of dedicated land, which is made available for the setup of businesses and industries. Having the Hambantota Port declared as a free port eases financial burdens in today’s fast-moving day and age for shippers and manufacturers to manage their cargo movement on import, export, and re-export. The Port Industrial Park follows and replicates the success of China Merchants Port’s strategic ‘PPC’ or Port, Park & City model. This model has enabled investors to benefit from considerable savings in cost and time as a result of having the port within close proximity to their manufacturing plant. The industrial park has demarcated and classified 3 industry clusters as Heavy Industries, Light Industries, and Food processing industries.

Plug and Play ‘Park in Park’ Manufacturing Facility

In June this year, HIP has partnered with Shenzhen Xinji Group to set up a $16 million high-tech plug and play ‘Park in park’ manufacturing facility within the port’s industrial zone, spread over an area of 9,000 square meters. The project went into construction within 20 days of signing the partnership agreement with Hambantota International Port Group (HIPG). The concept is a fully-fledged stand-alone industrial facility with some very unique features, set to operate within the Hambantota International Port’s Industrial Zone. This project will promote the production and manufacturing of household electric and electronic appliances. This will make Sri Lanka an attractive destination for manufacturers who do not wish to go through the hassle of setting up factories but would rather use readymade services and hit the ground running, with no delays in production.

The Plug and Play concept is not a new type of factory or building but a set of manufacturing standards that are needed to achieve plug and play capability on the factory floor. The easiest way to understand it is to think of how your office is now networked. All is controlled more or less at a central point for computer systems, telephony, printers and even building management and when something goes wrong you call IT. This is very much the same way. The entire factory is operating on a set parameter of communication standards, the machines are networked so that all activity is monitored in real-time and can even be managed remotely. Therefore, under this concept, where a user literally only needs to ‘plug’ in an additional device, such as a USB stick, into a PC and it will start working or ‘play’. Being able to ‘add on’ software or hardware as needed to improve manufacturing quality or output is a major step in industrial production processes which are typically more rigid and require costly expertise to adjust even the smallest parameter.

Another benefit that the Plug and Play Factory concept can offer is the ability to do far more in a much more limited space. Some industries particularly that of small businesses are limited by size and funding capabilities, but with higher efficiency due to the interoperability standards can allow for those limitations, even work with them better. Under the interoperability standards, Plug and Play is designed to enable standardized communication among devices from different suppliers. This allows smaller businesses to maximize the use of the property to achieve higher levels of production. Many factories are using third less space to accomplish the same thing that they previously needed far more space to do. This saves the company money on personnel, space, utilities, and on other expenses for the production.

The ‘Park in park’ concept is where all the facilities for an investor are supplied by the management, right down to clearing red tape, infrastructure hurdles, and even human resources needed for a smooth-running business. This model would be attractive to investors as it would considerably reduce the start-up investment costs while avoiding the hassle and costs involved in setting up factories. Potential investors would be able to avail themselves of direct “check-in” services, which will help speed up production time. They also facilitated the development of industrial clusters allowing tremendous economies of scale and scope for industries.

South Asian Market

In addition to that, industries operating within the HIP plug and play park in park facility will have the added benefits of the Industrial zone’s free port policy and free trade agreement, enabling them to provide quality products to Sri Lanka and surrounding countries. It would be a great plus for light industry manufacturers and traders who wish to come and set up in Sri Lanka with a view to finding markets in South Asia. Since 2014, South Asia has been one of the fastest-growing subregions in the world, and economic growth is largely driven by domestic demand therefore its less affected by global economic developments. Strong growth in South Asia has been largely driven by the performance of Bangladesh and India. South Asian domestic demand in terms of consumption and investment has been strong and expected to remain strong due to the large development and investment needs.

Therefore, there is great potential for investors around the world to look at HIP as a manufacturing hub for production and for sale into the South Asian markets and leap into East Africa and to Southeast Asia by using the excellent connectivity from Hambantota Port and Plug and Play ‘Park in Park’ Manufacturing Facility.

Furthermore, China is moving up the value chain through its huge investments in technology, artificial intelligence, robotics and blockchain, in turn Chinese companies are developing and producing more higher valued goods. Therefore, some of manufacturing now moving out of China. Sri Lanka use this opportunity to attract some of the manufacturer from China to HIP as well.

Conclusion

A well-developed strategically located Port and Plug and Play ‘Park in Park’ Manufacturing Facility in Hambantota well to bolster its role as a global manufacturing hub. This faciality can attract foreign manufacturers to set up their facilities, and this can bring foreign direct investment (FDI), generate employment, foreign exchange earnings, exports, and government revenues. In addition, industrial zones can facilitate skills upgrading, technology transfer, adoption of modern management practices, and economic diversification. The facility can also ensure downstream benefits to other Sri Lankan companies as the industries operating within the park will be encouraged to use Sri Lankan raw materials and services.

Maya Majueran is a PhD Doctoral Student at the University of Kelaniya, Sri Lanka. He is carrying out research on the Implications of China's Belt and Road Initiative (BRI) on HRD in Sri Lanka’s Maritime Logistics Sector. He is an associate member (AMCIPM) of Chartered Institute of Personnel Management (CIPM), Sri Lanka. Maya currently serves as a Director of BRISL, a Sri Lankan think tank focusing on China’s Belt and Road Initiative (BRI). He has extensive experience in support functions in the Humanitarian Aid sector. Maya can be contacted at: mayalk2000@gmail.com